Network Cabling Help - Copyright © 2016 - All rights reserved. - Privacy and Cookie Policy

A guide to the method of joining fibers

Fusion Splicing

There are several reasons for splicing a fiber cable, these include: • To join two fibers due to a breakage. • To connect some of the cores straight through a patch cabinet. • To extend a cable run. • To reduce losses, a fusion splice has much lower losses than two connectorized cables joined through a coupler.

•

Or to attach a pre-terminated pigtail.

A Pigtail is a short length of fiber with a factory fitted and polished connector. In the past these were used

connectorized cables joined through a coupler.

•

Or to attach a pre-terminated pigtail.

A Pigtail is a short length of fiber with a factory fitted and polished connector. In the past these were used in preference to field terminations because of the complexities at the time of manually terminating optical

in preference to field terminations because of the complexities at the time of manually terminating optical fibers. These days pigtails are mainly used where the environment isn't suitable for manual terminations

fibers. These days pigtails are mainly used where the environment isn't suitable for manual terminations or where speed is a factor.

As with all fiber termination methods, safety is very important so first some safety tips.

or where speed is a factor.

As with all fiber termination methods, safety is very important so first some safety tips. •

Always work in a clean and tidy area.

•

Fiber offcuts are hard to see and can easily penetrate the skin especially if they get into your

clothes, so care must be taken to ensure the safe disposal of all offcuts. Dispose of fiber scraps

immediately using a suitable container and do not throw into a waste paper bin.

•

Because of the dangers of ingesting a fiber, do not eat or drink in the termination area.

•

Fusion splicers use an electric arc to fuse the fibers together so they should never be used in an

environment where flammable gases or liquids are present.

•

Never look into the end of a live fiber connector. Holding some multimode fibers up to a piece of

paper may prove the presence of light and therefore prove that it is live, but it doesn't prove that it

isn't live! Some laser powered equipment use light which is outside of the visible spectrum, so err

on the side of caution.

•

Always work in a clean and tidy area.

•

Fiber offcuts are hard to see and can easily penetrate the skin especially if they get into your

clothes, so care must be taken to ensure the safe disposal of all offcuts. Dispose of fiber scraps

immediately using a suitable container and do not throw into a waste paper bin.

•

Because of the dangers of ingesting a fiber, do not eat or drink in the termination area.

•

Fusion splicers use an electric arc to fuse the fibers together so they should never be used in an

environment where flammable gases or liquids are present.

•

Never look into the end of a live fiber connector. Holding some multimode fibers up to a piece of

paper may prove the presence of light and therefore prove that it is live, but it doesn't prove that it

isn't live! Some laser powered equipment use light which is outside of the visible spectrum, so err

on the side of caution.

Overview

A fusion splice is a way of joining two fiber cores by melting the ends together using an electric arc. A

melting the ends together using an electric arc. A splicing machine is used because an extremely high

splicing machine is used because an extremely high degree of accuracy is needed, the machine first has

degree of accuracy is needed, the machine first has to align the cores and then apply the exact amount of

to align the cores and then apply the exact amount of heat to melt the ends before pressing them together.

Splicing can be carried out using a mechanical splice

heat to melt the ends before pressing them together.

Splicing can be carried out using a mechanical splice but these only hold the fiber ends together, precisely

but these only hold the fiber ends together, precisely aligned but not permanently joined.

There are four basic steps to fusion splicing

1.

Strip back all coatings down to the bare fibers and clean using isopropyl alcohol.

2.

Cleave the fibers using a precision cleaving tool and put the heat shrink tube on to one of the ends.

3.

Fuse the fibers together in the fusion splicer.

4.

Put the heat shrink protector on the fiber joint.

aligned but not permanently joined.

There are four basic steps to fusion splicing

1.

Strip back all coatings down to the bare fibers and clean using isopropyl alcohol.

2.

Cleave the fibers using a precision cleaving tool and put the heat shrink tube on to one of the ends.

3.

Fuse the fibers together in the fusion splicer.

4.

Put the heat shrink protector on the fiber joint.

Fusion Splicing Method

Stripping

Strip back the external sheathing of the cable using a rotary stripping tool. Cut back the aramid strength member using ceramic or kevlar scissors.

member using ceramic or kevlar scissors. Strip the primary buffer from the fiber using fiber

Strip the primary buffer from the fiber using fiber strippers not ordinary wire strippers. Do this a small

strippers not ordinary wire strippers. Do this a small section at a time to prevent the fiber breaking, about

section at a time to prevent the fiber breaking, about 10mm (3/8 in) on each cut is fine until you get used

10mm (3/8 in) on each cut is fine until you get used to it. Strip back about 35mm (1.5 in).

Clean the bare fiber with a lint free wipe and

to it. Strip back about 35mm (1.5 in).

Clean the bare fiber with a lint free wipe and isopropyl alcohol, it will "squeak" when it is clean.

isopropyl alcohol, it will "squeak" when it is clean.

Cleaving

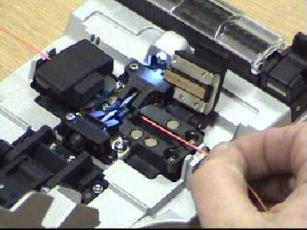

The cleaver first scores the fiber and then pulls the fiber apart to make a clean break. It is important that

fiber apart to make a clean break. It is important that the the ends are smooth and perpendicular to get a

the the ends are smooth and perpendicular to get a good joint, this is why a hand held cleaver will not do.

good joint, this is why a hand held cleaver will not do. Cleavers vary from manufacturer to manufacturer and

Cleavers vary from manufacturer to manufacturer and you should read the instructions for the one you are

you should read the instructions for the one you are using. Basically the operation consists of putting the

using. Basically the operation consists of putting the fiber into the groove and clamping, then close the lid

fiber into the groove and clamping, then close the lid and press the lever. Easy eh!

Good cleaving tools can cost between $800 to $3000

and press the lever. Easy eh!

Good cleaving tools can cost between $800 to $3000

The Fusion Process

Once the fiber ends are prepared they are placed in the fusion splicer. Press the button and the machine

the fusion splicer. Press the button and the machine takes care of the rest of the fusion process

takes care of the rest of the fusion process automatically.

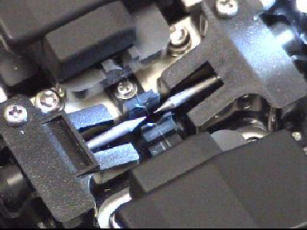

First the two fibers are aligned, you can see this on

automatically.

First the two fibers are aligned, you can see this on the photo where a much magnified image shows the

the photo where a much magnified image shows the two fiber ends. The display also shows how well the

two fiber ends. The display also shows how well the cleaver does its job of producing a perfect 90 degree

cleaver does its job of producing a perfect 90 degree cut.

If you watch very carefully in the video you can see

cut.

If you watch very carefully in the video you can see the X and Y alignment that takes place. The splicer

the X and Y alignment that takes place. The splicer aligns the fibers on one axis and then from another

aligns the fibers on one axis and then from another camera angle set at at 90 degrees, it aligns the other

camera angle set at at 90 degrees, it aligns the other axis. This high precision alignment is critical for a low

axis. This high precision alignment is critical for a low loss joint, any mismatch of the fiber cores will

loss joint, any mismatch of the fiber cores will significantly reduce the propagation of light through

significantly reduce the propagation of light through the joint.

Bearing in mind that we are dealing with two very

the joint.

Bearing in mind that we are dealing with two very small glass rods of only 125 microns in diameter, it

small glass rods of only 125 microns in diameter, it brings it home as to how extremely accurate these

brings it home as to how extremely accurate these machines are.

Once the fibers are aligned the splicer fires an

machines are.

Once the fibers are aligned the splicer fires an electric arc between the two ends which melts them

electric arc between the two ends which melts them immediately and pushes them together, or fuses

immediately and pushes them together, or fuses them into one piece of fiber.

The fusion splicer then tests for dB loss and tensile

them into one piece of fiber.

The fusion splicer then tests for dB loss and tensile strength before giving the "OK" beeps for you to

strength before giving the "OK" beeps for you to remove the splice from the machine.

remove the splice from the machine.

Protection

The splicer in the video has a built in heat shrink oven, so when the fiber is taken out of the machine

oven, so when the fiber is taken out of the machine the protective tube is slid into place and the whole

the protective tube is slid into place and the whole assembly is put into the oven to shrink the tube on to

assembly is put into the oven to shrink the tube on to the splice.

The protective tube gives physical protection to the

the splice.

The protective tube gives physical protection to the splice and further protection is provided by placing

splice and further protection is provided by placing the splice into a splice tray.

Once all of the fibers have been joined the whole

the splice into a splice tray.

Once all of the fibers have been joined the whole tray is then fixed into a splice box which protects the

tray is then fixed into a splice box which protects the cable joint as a whole and the cable clamps are then

cable joint as a whole and the cable clamps are then tightened to prevent any external forces from pulling

tightened to prevent any external forces from pulling on the splices.

Fusion splicers are expensive and can cost between

on the splices.

Fusion splicers are expensive and can cost between about $5,000 to over $30,000, so you need to be

about $5,000 to over $30,000, so you need to be doing a lot of splicing to justify the initial outlay but,

doing a lot of splicing to justify the initial outlay but, for a low loss and relatively fast connection it is the

for a low loss and relatively fast connection it is the only tool for the job.

only tool for the job.

Fusion Splicing a Fiber Optic Cable