Network Cabling Help - Copyright © 2016 - All rights reserved. - Privacy and Cookie Policy

. . . with an SC connector using the cold cure method.

Cold Cure Termination

There are several different methods of terminating fiber cables including heat-cured, cold cured, pre-injected epoxy, UV adhesives and crimped termination's. There are also environmental conditions to take into consideration, but for the purpose of this

also environmental conditions to take into consideration, but for the purpose of this tutorial we will discuss the cold cure method as it is the most widely used system

tutorial we will discuss the cold cure method as it is the most widely used system and probably the easiest to learn. It is also preferable on site as it doesn't require a

and probably the easiest to learn. It is also preferable on site as it doesn't require a power source for ovens and fusion splicers.

As with all fiber termination methods, safety is very important so first some safety

tips.

•

Always work in a clean and tidy area.

•

Fiber offcuts are hard to see and can easily penetrate the skin especially if they get into your

clothes, so care must be taken to ensure the safe disposal of all offcuts. Dispose of fiber scraps

immediately using a suitable container and do not throw into a waste paper bin.

•

Because of the dangers of ingesting a fiber, do not eat or drink in the termination area.

•

Observe manufacturers recommendations when using solvent based adhesives.

•

Never look into the end of a live fiber connector. Holding some multimode fibers up to a piece of

paper may prove the presence of light and therefore prove that it is live, but it doesn't prove that it

isn't live! Some laser powered equipment use light which is outside of the visible spectrum, so err

on the side of caution.

On to the lesson . . . . . .

power source for ovens and fusion splicers.

As with all fiber termination methods, safety is very important so first some safety

tips.

•

Always work in a clean and tidy area.

•

Fiber offcuts are hard to see and can easily penetrate the skin especially if they get into your

clothes, so care must be taken to ensure the safe disposal of all offcuts. Dispose of fiber scraps

immediately using a suitable container and do not throw into a waste paper bin.

•

Because of the dangers of ingesting a fiber, do not eat or drink in the termination area.

•

Observe manufacturers recommendations when using solvent based adhesives.

•

Never look into the end of a live fiber connector. Holding some multimode fibers up to a piece of

paper may prove the presence of light and therefore prove that it is live, but it doesn't prove that it

isn't live! Some laser powered equipment use light which is outside of the visible spectrum, so err

on the side of caution.

On to the lesson . . . . . .

The Connector

There are three parts to a fiber connector (four if you count the dust cap) they are: The connector housing, the connector body and the strain relief boot.

The body contains the ferrule which aligns the fiber

connector body and the strain relief boot.

The body contains the ferrule which aligns the fiber perfectly for mating with another connector, it's a precision

perfectly for mating with another connector, it's a precision engineered component. The housing contains the fiber body and provides the latching mechanism. The

engineered component. The housing contains the fiber body and provides the latching mechanism. The strain relief boot prevents the fiber from bending past the critical point at which it can break.

strain relief boot prevents the fiber from bending past the critical point at which it can break.

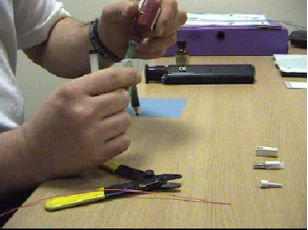

Preparation

Fill the syringe with adhesive ready to use. Strip back the external sheathing of the cable using a rotary stripping tool.

Cut back the aramid strength member using ceramic

a rotary stripping tool.

Cut back the aramid strength member using ceramic or kevlar scissors.

Slide the strain relief boot onto the fiber to be

or kevlar scissors.

Slide the strain relief boot onto the fiber to be terminated.

Strip the primary buffer from the fiber using fiber

terminated.

Strip the primary buffer from the fiber using fiber strippers not ordinary wire strippers.

Do this a small section at a time to prevent the fiber breaking, about 10mm (3/8 in) on each cut is fine

strippers not ordinary wire strippers.

Do this a small section at a time to prevent the fiber breaking, about 10mm (3/8 in) on each cut is fine until you get used to it. Strip back about 30mm (1.25 in).

until you get used to it. Strip back about 30mm (1.25 in).

"Sticking" on the connector!

Inject the adhesive into the connector body until a small bead appears at the end of the ferrule.

Clean the bare fiber with a lint free wipe and isopropyl

bead appears at the end of the ferrule.

Clean the bare fiber with a lint free wipe and isopropyl alcohol, it will "squeak" when it is clean.

alcohol, it will "squeak" when it is clean. Apply the primer to the bare fiber either with the brush

Apply the primer to the bare fiber either with the brush supplied or by dipping it into the bottle.

Push the fiber in to the connector body in one smooth

supplied or by dipping it into the bottle.

Push the fiber in to the connector body in one smooth action until you feel the buffer reach the back of the

action until you feel the buffer reach the back of the ferrule.

The chemical reaction between the adhesive and the primer happens almost instantly so don't stop while

ferrule.

The chemical reaction between the adhesive and the primer happens almost instantly so don't stop while inserting the fiber otherwise it will stick before it is fully home.

inserting the fiber otherwise it will stick before it is fully home.

Cleaving

The purpose of cleaving the fiber is to ensure that it breaks cleanly at 90 degrees, although you may

breaks cleanly at 90 degrees, although you may think that because it is ground down to the ferrule

think that because it is ground down to the ferrule and then polished it wouldn't make any difference if it

were just snapped off! It makes a big difference. If

and then polished it wouldn't make any difference if it

were just snapped off! It makes a big difference. If the fiber shatters or splinters down past the ferrule

the fiber shatters or splinters down past the ferrule then no amount of polishing will turn it into a good

then no amount of polishing will turn it into a good connection. A hand held scribe or pen cleaver is

connection. A hand held scribe or pen cleaver is adequate for this job, unlike fusion splicing where a

adequate for this job, unlike fusion splicing where a perfectly cleaved end is essential for a good

perfectly cleaved end is essential for a good connection.

Lightly scribe the fiber as close to the ferrule as

connection.

Lightly scribe the fiber as close to the ferrule as possible and use a slight tug to break the fiber end away. Dispose of the fiber off-cut immediately in the

possible and use a slight tug to break the fiber end away. Dispose of the fiber off-cut immediately in the hazardous debris container.

hazardous debris container.

Polishing

The first step in polishing is to take the fiber down to the ferrule, for this we use about a 9 micron lapping

the ferrule, for this we use about a 9 micron lapping film. Hold the connector in one hand and rub the nub

film. Hold the connector in one hand and rub the nub of fiber down to the ferrule with the lapping film.

of fiber down to the ferrule with the lapping film. When it is close enough you will feel it get smoother.

Step two. Insert the connector into the polishing

When it is close enough you will feel it get smoother.

Step two. Insert the connector into the polishing puck, this keeps it perpendicular to the polishing

puck, this keeps it perpendicular to the polishing surface. Place a sheet of 2 micron lapping film on a

surface. Place a sheet of 2 micron lapping film on a suitable flat surface.

Hold the connector and puck, and place it on the

suitable flat surface.

Hold the connector and puck, and place it on the polishing surface. Then move it in a figure of 8

polishing surface. Then move it in a figure of 8 pattern about 30 times using slight pressure. The end is now polished and can be inspected with the

pattern about 30 times using slight pressure. The end is now polished and can be inspected with the microscope. Some people recommend 3 or 4 stages of polishing but we find that we get just as good

microscope. Some people recommend 3 or 4 stages of polishing but we find that we get just as good results from just these two grades of abrasives.

results from just these two grades of abrasives.

Visual Check

Using the illuminated microscope check that the polished end is OK. Things to look out for are

polished end is OK. Things to look out for are excessive scratches or remnants of the epoxy

excessive scratches or remnants of the epoxy adhesive. You can now fit the housing and dust

adhesive. You can now fit the housing and dust cap.

cap.

Testing

Once both ends are terminated the fiber can be tested. Fiber testing used to involve a bulky OTDR

tested. Fiber testing used to involve a bulky OTDR (Optical Time Domain Reflectometer) operated by a geek with a degree in optical physics, but these days

a simple hand held light source and power meter can be used. To give it a full test you can also use a

(Optical Time Domain Reflectometer) operated by a geek with a degree in optical physics, but these days

a simple hand held light source and power meter can be used. To give it a full test you can also use a fiber certification tool which simply tells you what

fiber certification tool which simply tells you what systems the fiber is good for. These simple to use

systems the fiber is good for. These simple to use (but quite expensive) instruments will give a print out

(but quite expensive) instruments will give a print out of all test parameters and losses as well as the

of all test parameters and losses as well as the communications media it will work on.

communications media it will work on.

Terminating a Fiber Optic Cable . . .